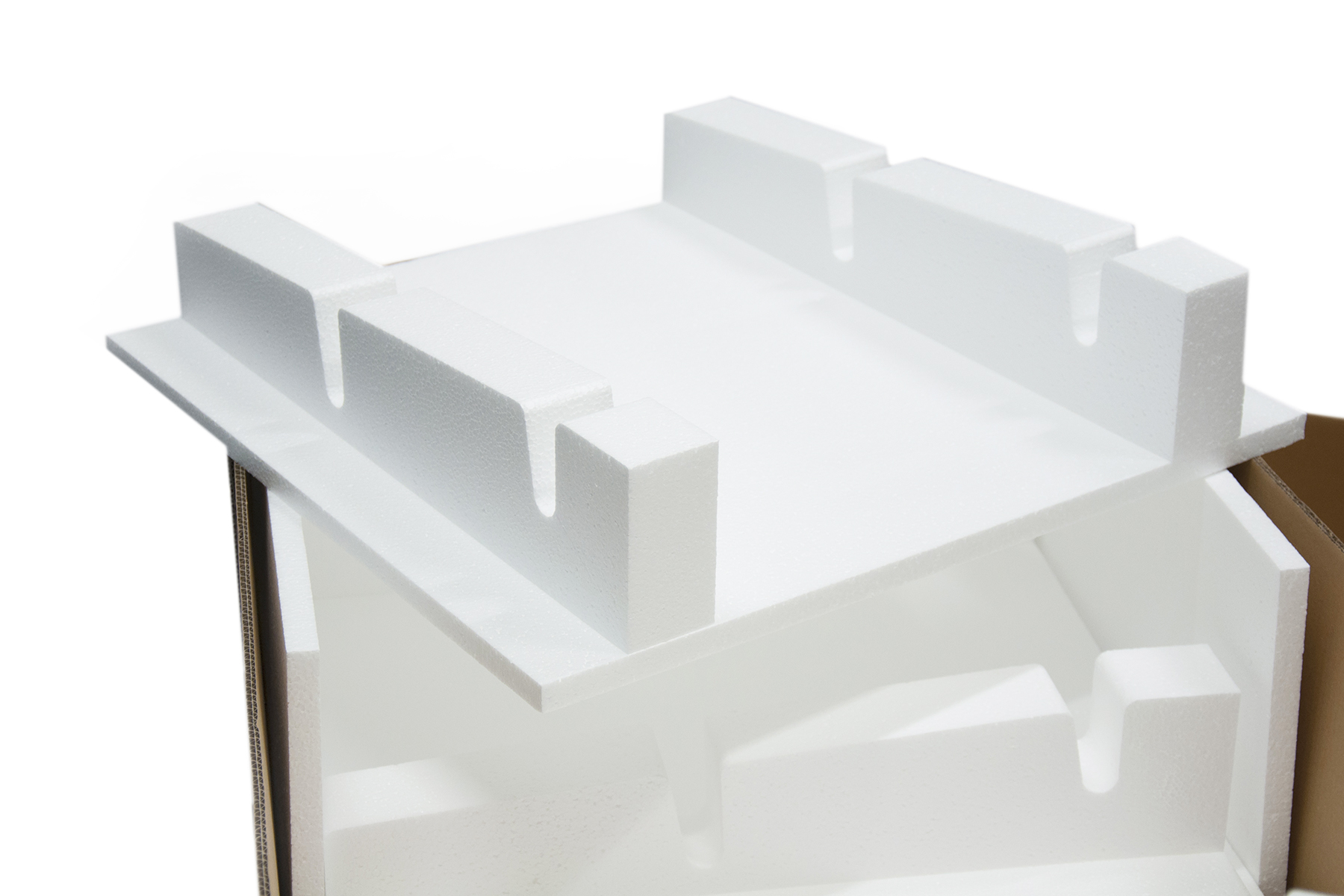

Packaging foams

We can select the foams that are the most appropriate for the given task. From our portfolio, we can typically choose the material satisfying any protection requirement, from the cheapest low-density EPS – polystyrene foams to the PUR – polyurethane technological foams, and to the PE/XPE – polyethylene foams that can even be used in returnable packagings. In our case the plastic foams become “green” solutions by dimensioning them for the achievement of adequate product protection considering the given task, and with the achievement of adequate product protection, we use as little of them as possible. Its necessity is supported by the fact that the use of the traditionally environment-friendly corrugated cardboard based inserts is limited: they typically cannot withstand multiple drops; because of their rheological properties, they get compressed and stop protecting the product in the transport chain – as opposed to the designed plastics, which provide perfect protection throughout the chain.

The foams can be manufactured by various technologies; even customized single piece CNC-milled formworks can be prepared.

The PE foams are also made in the ESD dissipative (pink foam) or the “leathery” high density layer format (foldable foam).

Category

Disposable